Welcome to Metalife Solutions

3Layer Polyethylene Coating

Product Description

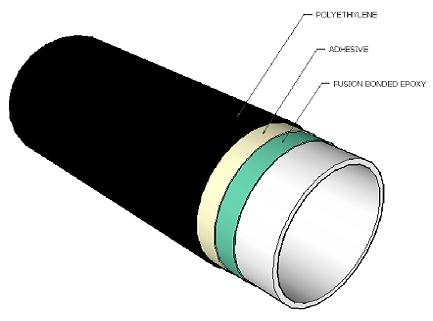

The 3 layer polyethylene coating (3LPE) is a multilayer coating composed of three functional components

- FBE Primer

- A Grafted Copolymer Adhesive

- Outer Layer of Polyethylene.

This provides an excellent corrosion protection and mechanical protection for oil and gas pipelines at operating temperature up to 80oC.

The 3LPE System achieves superior long term corrosion resistance and excellent mechanical protection for small and large diameter pipelines operating at high temperature .This is due to strong adhesion of FBE to steel and the tough outer layer of high density polyethylene. The 3LPE system can be applied in a various range of thicknesses to meet project specifications and requirements.

The three coating layers in 3-LPE coated pipe are as below.

- Layer 1: FBE Primer: corrosion protective layer. This layer consists of fusion bonded epoxy which has a very good bonding with the blasted steel surface which offers excellent corrosion protection.

- Layer 2: A Grafted Copolymer Adhesive The copolymer adhesive is a maleic anhydride grafted polyethylene compound. This material has good chemical bonding to the fusion bonded epoxy and the top layer which is polyethylene.

- Layer 3: Polyethylene Layer This is the top layer for physical protection which is similar to the copolymer adhesive that makes them bond well with each other.

Standards And Specifications

3LPE pipes are manufactured according to the following standards:

- DIN 30670

- CSA Z245.21

- ISO 21809-1

Special Features Of 3lpe Coated Pipes:

Corrosion Resistance

- 3LPE Coating prevents steel pipe from corrosion.

- Excellent chemical resistance properties and resistance to cathodic disbondment.

- 3LPE Coating has got good resistance to moisture permeability.

Long Working Life

- Pipe has constant performance characteristics through out the life span. Service life of more than 75 years.

High Bond Strength

- The external and internal 3LPE coating and lining is bonded firmly to the mild steel pipe surface and the mean adhesion strength is 125 kg/cm² (ASTM D 4541).

Customized Solutions

- 3LPE external coating can be applied from diameters 25 mm to 3000 mm with lengths of up to 12m.

Mechanical Protection

- Top coat of polyethylene prevents abrasion and damage to fusion bonded epoxy during handling.

- Polyethylene topcoat permits use of local material without relying on specific backfilling material.

Applications

3LPE coated steel pipes are used in the following applications where the pipes are either buried or submerged:

- Drinking water pipelines.

- Oil and gas pipelines

- In plant process water applications

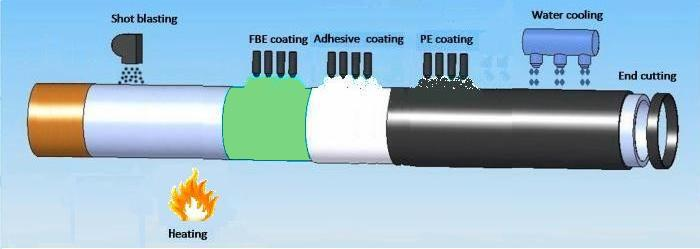

Manufacturing Procedure

Manufacturing Capabilities

- Diameter range - 25 mm to 3000 mm

- Pipe length - 6 m to 12 m

- Operating temperature range - -40o C to 100o C

- Coating thickness - Maximum up to 4.2 mm