Welcome to Metalife Solutions

Fusion Bonded Epoxy coating

Product Description

Fusion bonded epoxy coating on steel pipes in diameter ranges from 25 mm to 3000 mm. This coating provides excellent resistance to corrosion, chemical and cathodic disbondment.

Fusion-bonded epoxy (FBE) coatings are thermoset hardening layers of epoxy resin applied to steel pipes using an electrostatic process, which protects them against corrosion. FBE coatings are well known for their anti-corrosion properties over a wide temperature range. It provides a very good bonding with the blasted steel surface.

Standards And Specifications

Fusion bonded epoxy coated pipes are manufactured according the following standards:

- CSA Z245.20

- AWWA C 213

- IS 3589 Annex C

- ISO 21809-2

Features Of Fbe Coated Pipes

Corrosion Resistance

- FBE Coating prevents steel pipe from corrosion

- Excellent chemical resistance properties and resistance to cathodic disbondment.

Long Working Life

- Coated pipe has constant performance characteristics throughout the life span. Service life of more than 75 years.

High Bond Strength

- The FBE coating is bonded firmly to the mild steel pipe surface and the mean adhesion strength is 125 kg/cm² (ASTM D 4541).

Customized Solutions

- FBE coating can be applied from diameters 25 mm to 3000 mm with lengths of up to 12m.

Environment Friendly

- FBE coating are applied in powder form and there is no need for resin hardener.

Applications

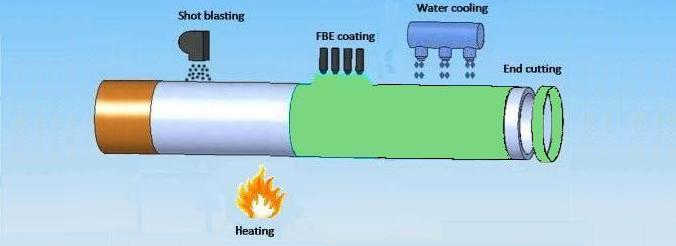

FBE coating is an industry standard in corrosion protective coatings. It is environmentally-safe thermosetting polymer coating which is used as corrosion protection for pipe valves and fittings. Typical coating application temperatures are usually in the range of 180° C to 250° C (360° F to 480° F). When the FBE is applied to the pre-heated pipe with the help of electrostatic spraying machine, the FBE film wets and flows onto the steel surface and soon becomes a solid coating by chemical cross-linking.

FBE coated steel pipes are used in the following applications where the pipes are either buried or submerged:

- Drinking water pipelines.

- Oil and gas pipelines

- In plant process water applications

Manufacturing Procedure

Manufacturing Capabilities

- Diameter range - 25 mm to 3000 mm

- Pipe length - 6 m to 12 m

- Operating temperature range - -40o C to 100o C

- Coating thickness - Maximum up to 750 microns